Ohio State University Engineering Students Explore Fire Safety in Microgravity with Laser Welding Technology

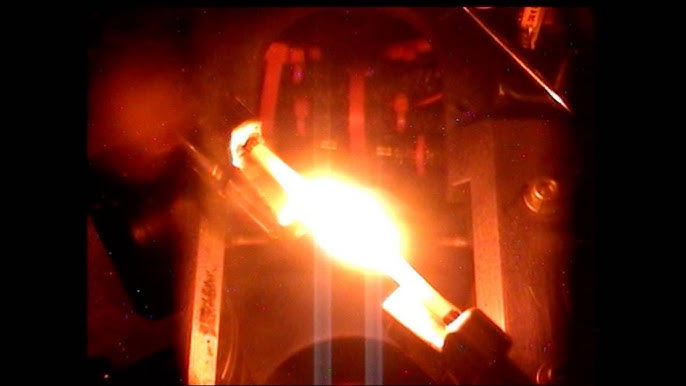

Columbus, OH — Engineering students from Ohio State University are pushing the boundaries of space safety research, exploring fire behavior and safety protocols while testing advanced laser welding technology in microgravity. As part of their capstone project, these students are examining how laser welding can be safely performed in low-gravity environments — a critical study as space agencies and commercial companies continue to expand human activities in orbit.

The unique experiment, conducted in collaboration with NASA, seeks to understand how fire might behave differently in microgravity conditions, where standard methods of heat dissipation, combustion, and fire suppression are dramatically altered. The students are focused on refining welding techniques to enhance safety and effectiveness, aiming to make these processes viable for future space construction and maintenance projects.

“Space presents entirely new challenges for welding and fire prevention,” explained Dr. Sarah Young, a professor of engineering at Ohio State and advisor for the project. “In microgravity, even small sparks can spread differently, and typical fire behavior models don’t always apply. Our students’ work could help develop safer welding technology for use beyond Earth.”

The capstone team is using simulation models to assess how heat and particles disperse during laser welding in microgravity, aiming to enhance safety protocols that address potential fire hazards. These findings will also contribute to NASA’s goals of developing sustainable space habitats and in-orbit construction capabilities.

Once complete, the students hope their project will provide valuable insights to aerospace companies, possibly influencing new standards for space manufacturing safety. Their innovative research underscores the vital role of university-led engineering initiatives in advancing space exploration.